designed to provide our customers sustainable value.

Propeller shafts

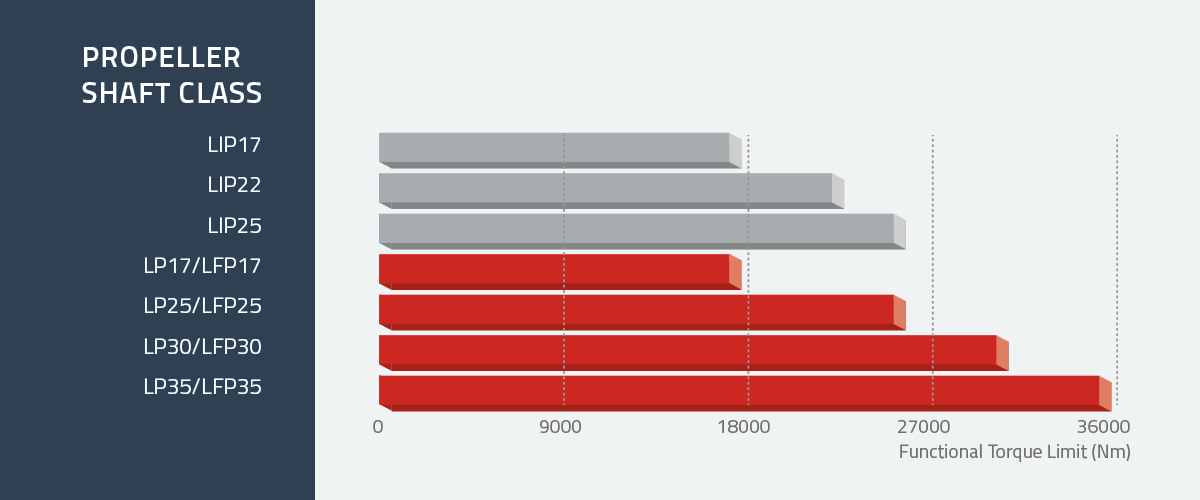

For more than a decade LEAX Group provides Propeller Shafts to the Commercial Vehicle Industry, on ranges from 17 kNm up to 35 kNm. LEAX Research and Development center in Sweden is complete with a full-length test rig, 3D-printers and a highly experienced staff.

Details

- LEAX propeller shafts are designed to provide our customers sustainable value

- World class manufacturing process, including the most reliable welding process between the joints and automated balancing process with Quality G16

- LEAX prop shafts are well known for their longevity, is market leading

- LEAX develop tailor made solutions in cooperation with customers and produce a unique LEAX-branded line of prop shafts as well

- Among the alternatives are different interface solutions (Yokes and Flanges KV150, KV180 or customized), lubricated bearings, maintenance free bearings and an almost indifferent choice of lengths, widths, and angles

LP

Propeller Shafts, with compensation length

Propeller Shafts, with compensation length

LFP

Fixed Shafts, without compensation length

Fixed Shafts, without compensation length

LIP

Interaxle Shafts, with compensation length

Interaxle Shafts, with compensation length

Propeller Shafts for the Commercial Vehicle Industry

Contact

Gabriel Kleinke

Head of Propeller Shaft Development

T +5541 3641-6300Head of Propeller Shaft Development

M +46 76 102 45 55